How Much Does Polished Concrete Cost in Brisbane & Gold Coast?

Polished concrete has become the go-to look across the Gold Coast and Brisbane, from waterfront apartments in Broadbeach to busy cafés in West End. It’s modern, tough and easy to maintain. Done right, it delivers a seamless, architectural finish that handles high foot traffic and our humid subtropical climate with minimal fuss.

In this guide, we unpack:

how much does polished concrete cost? You’ll learn what really moves the price up or down, how different finish types compare, ways to save on the cost of a

polished concrete floor and when it pays to bring in a specialist team like Coulson’s Concrete Finishes.

What Is Polished Concrete?

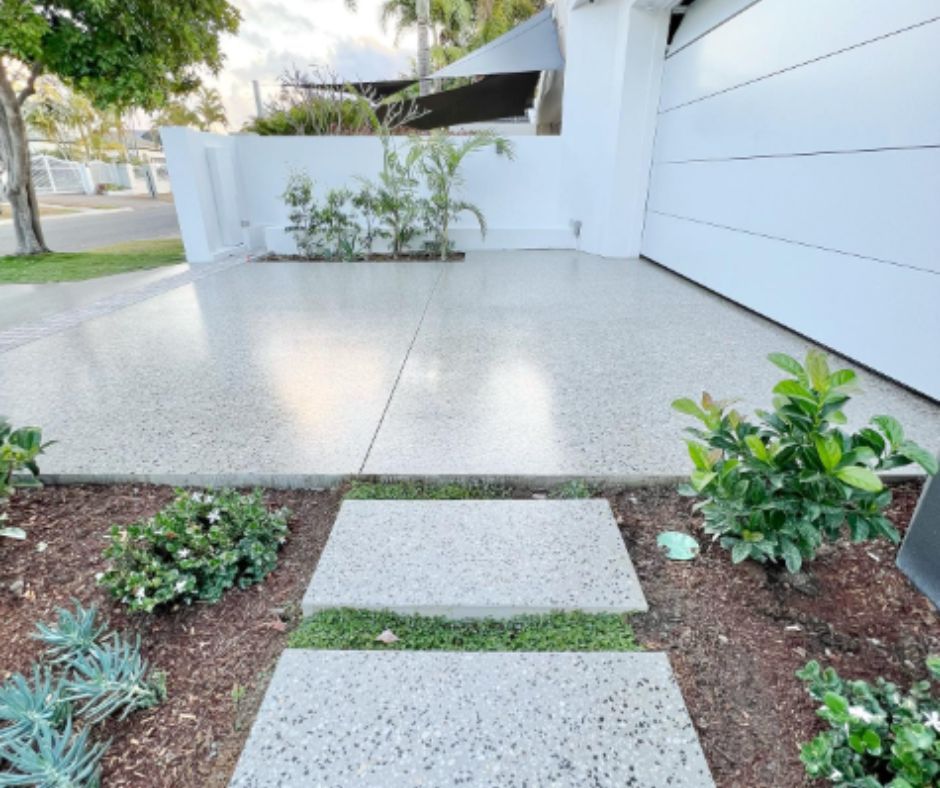

Polished concrete is an existing concrete slab that’s ground, densified and polished with progressively finer diamond tooling. The result is a durable, low-porosity surface with a custom gloss level (from matte to mirror-like finish).

Compared with tiles, timber or vinyl, polished concrete offers seamless spans with fewer joints, fewer places for grime to settle and a long lifecycle. You’ll find it in residential living spaces, commercial building surfaces and in light-industrial spaces where abrasion resistance matters.

How Much Does Polished Concrete Cost in Australia?

Polished concrete pricing isn’t one-size-fits-all. The final cost of a polished concrete depends on the condition of your existing slab, the level of aggregate exposure and the level of finish you’re after. Because every floor is unique, quotes are tailored to each surface, not pulled out from a template.

Think in terms of spaces rather than square metres. A simple single-car garage with easy access typically sits at the lower end of the price range of the polished concrete cost, while a spacious living area with edging, stairs or needed repairs will add time and complexity to the job.

For an accurate quote, share your location, floor area, photos or plans, preferred exposure and gloss and any known issues like cracks or old adhesives. Coulson's Concrete Finishes can then inspect if needed and provide a clear, itemised proposal and cost of a polished concrete floor so you know exactly what’s included.

Key Factors That Influence the Polished Concrete Cost

The cost of polished concrete floor is tailored to a few core variables, such as:

Size and Scope of the Project

Smaller areas attract minimum mobilisation charges, while larger spaces often dictate higher rates. Complex layouts (stairs, pillars, tight edges) add time for edging and detail work.

Existing Slab Condition

Damaged, uneven or contaminated slabs require extra preparation such as crack filling, patching, levelling or adhesive removal. The more remediation needed, the greater the labour and tooling involved.

Type of Finish & Gloss Level

Each type of polish involves different steps and materials, which change labour time. Moreover, higher gloss levels typically need additional refinement passes.

Aggregate Exposure Level

Cream (nil exposure) requires minimal grinding, while “salt & pepper” or full-stone exposure needs deeper grinding and more passes. Greater exposure delivers a stronger visual statement but increases labour.

Location and Accessibility

Transportation and tight access (e.g., CBD sites or high-rises) affect setup and productivity. Regional differences and after-hours requirements can also influence scheduling and labour.

Labour and Time Requirements

Polishing is a multi-stage process that may include curing windows, sequencing and dust control. Longer timelines or working around other trades increase labour hours.

Comparing the Costs of Polished Concrete Floors

Finish choice directly impacts how much does polished concrete costs because deeper grinding and higher refinement require more time, tooling and edge work.

Cream Polish (Light Grind):

A clean, minimalist look with nil aggregate exposure achieved through very light grinding, typically the least labour-intensive when the slab is already in good condition.

Salt & Pepper:

Lightly exposes the fines for a subtle speckle, needs more grinding than cream but less than full stone exposure, so it generally sits mid-range on effort.

Full Exposure:

Reveals the aggregate across the whole surface and demands the most refinement, making it the highest labour/time option.

Tips to Reduce Polished Concrete Costs

A few smart planning moves can lower your overall polished concrete cost without sacrificing finish quality.

Combine services in one job

Bundling tasks and areas into a single booking cuts setup time, transportation and call-out overhead.

Schedule off-peak projects

Booking during quieter periods gives crews more flexibility and helps streamline labour and logistics.

Choose cost-effective finishes for large areas

Opt for durable finishes that need fewer refinement passes to control labour hours at scale.

Work with local, trusted providers like Coulson’s

A local, reputable team minimises travel times, sources efficiently and gets it right first time, avoiding costly rework.

Cost of Polished Concrete Floor vs Other Flooring Options

Here’s a quick look at how the cost of a polished concrete floor compares with other flooring options in terms of installation and long-term maintenance.

Tiles

Tiles can be comparable or lower to install, but they need frequent grout upkeep and potential regrouting.

Laminate/Vinyl

Laminate is quick and inexpensive to lay, but it can wear or lift sooner.

Carpet

Carpet is inexpensive to lay but needs frequent cleaning and periodic replacement.

Polished Concrete

Properly installed,

grind and sealed, polished concrete delivers decades of high abrasion and impact resistance, typically outlasting tiles, laminate, epoxy and carpet in busy spaces.

When to Contact a Professional & Get a Quote

Knowing when to bring in a specialist saves time, protects your slab and ensures the finish meets your expectations.

Signs You Need Expert Evaluation

If any of these sound or look familiar, a site assessment will prevent small issues from becoming costly problems:

- Cracks, spalling, pitting or surface delamination

- Moisture problems, efflorescence or dark “damp” patches that return after drying

- Uneven slabs, curling edges, high/low spots

- Old coatings/adhesives, sealers or paint that need safe removal

- Heavy oil/grease staining, rust marks or embedded contaminants

What to Ask in a Quote

Make side-by-side comparisons easy by asking:

- What surface preparation is included (repairs, grind, crack/joint treatment)?

- How will you manage slab moisture and uneven surface before polishing?

- Which grind level, aggregate exposure and gloss level are you quoting?

- How will you control dust and protect walls, fixtures and adjacent floors?

- How will you treat control/expansion joints and transitions to other floor types?

- What’s the project timeline, crew size, site access needs and working hours?

- What are the exclusions and warranty terms I should know about?

- Can you share recent local references and before/after examples for similar projects?

Why Choosing a Specialist Like Coulson’s Matters

Experienced crews are equipped with commercial-grade equipment and materials, a proven approach and deliver a consistent finish that lasts. Coulson’s also offers epoxy flooring, honed concrete and comprehensive surface prep and grinding services on the Gold Coast.

If you’re weighing options, message Coulson’s Concrete Finishes for an expert consultation and a tailored quote. We’ll map out a solution for your project so you can proceed with confidence, especially if you're unsure about how much polished concrete costs.

Key Takeaways:

- The average cost of polished concrete floor varies by scope, surface condition, access and local market dynamics, so there’s no single rate.

- The main drivers of polished concrete costs are project size, existing floor condition, finish level and location (including site access constraints).

- Mechanically polished concrete usually costs more upfront but delivers superior durability, gloss retention and long-term value.

- Always request a detailed, itemised, tailored quote that clarifies preparation, finish specs, timelines and exclusions before you start.

Frequently Asked Questions

How much does polished concrete cost per square metre in Australia?

It varies widely based on slab condition, finish level, access and region. The best way to know how much does polished concrete costs is to get a tailored polished concrete quote that is itemised and site-specific from our team.

Is polished concrete cheaper than tiles?

Upfront costs can be similar or vary either way, but polished concrete costs win on long-term value because it is typically lower due to reduced maintenance and replacement needs compared with grout-and-tile systems.

What’s the difference between grind and seal and mechanically polished concrete?

Grind and seal grinds the surface of the concrete, then applies a top sealer, while mechanically polished concrete hardens and refines the slab itself for a denser, longer-wearing shine with no film coating.

Does polished concrete crack over time?

Concrete can develop cracks from movement or substrate issues. Polishing doesn’t cause them, but a specialist like Coulson's Concrete Finishes can repair cracks and manage joints so polished concrete remains stable and attractive.

Can you polish an existing concrete floor?

Yes, provided the slab is sound. Coatings, adhesives or moisture issues may need remediation before achieving a consistent polished concrete finish.

Is polished concrete slippery when wet?

Properly specified polished concrete floors meet common slip requirements and you can boost traction with the right finish, conditioners or mats in wet zones.

How long does polished concrete last?

With correct specification and maintenance, polished concrete delivers long service life, retaining appearance and performance in busy residential and commercial spaces.

What kind of maintenance does it need?

Routine dust mopping, neutral-pH cleaning, and periodic burnishing keep polished concrete floors looking their best; grind-and-seal systems may also need resealing at intervals.

Are there eco-friendly benefits to polished concrete?

Yes, polished concrete uses the existing slab, avoids additional coverings, can be low-VOC, reflects light to reduce artificial lighting needs and lasts a long time.

Can I DIY polished concrete floors?

Small projects are possible, but consistent flatness, edge detailing and a uniform sheen are challenging without professional equipment and experience, so most homeowners choose Coulson's Concrete Finishes for polishing their concrete floor.