Can All Concrete Be Polished? Expectation vs Reality

If you’ve ever stood on a dusty old slab and wondered, “Can all concrete be polished?”, you’re not alone. A lot of Gold Coast homes and businesses were poured on basic construction slabs that were never designed as a “showpiece” floor, yet with the right prep, many of them can look like something out of a design magazine.

The catch? Not every slab is a good candidate. You’ve probably Googled things like “Can any concrete be polished?” or “Can any concrete floor be polished?”, only to find a mix of yes/no answers. The truth sits in the middle: almost any sound concrete slab can be polished, but soft mixes, major patching, high moisture, coatings and poor installation can change the game.

In this guide, you’ll get a clear verdict on when concrete can and can’t be polished, the key factors to decide if your slab is suitable, premium alternatives like grind & seal, honed and epoxy finishes when polishing isn’t ideal, and maintenance tips tailored to Gold Coast humidity, sand and salty air.

Quick Answer: Can All Concrete Be Polished?

On paper, concrete is an incredibly tough, polishable material, which is why so many Gold Coast homes, garages and showrooms use it as a finished floor. So can any concrete be polished in a literal sense? Almost, but only if the slab itself is up to the job.

If your slab is:

- Structurally sound (no major movement or crumbling)

- Reasonably flat and accessible with machines

- Dry enough for densifiers and sealers to work properly

- Free from severe oil, paint or chemical contamination

…then a true mechanical polish is usually achievable. Older slabs are often perfectly fine once old tiles, vinyl or carpet are removed and the surface is ground flat.

It’s also important to separate interior and exterior areas.

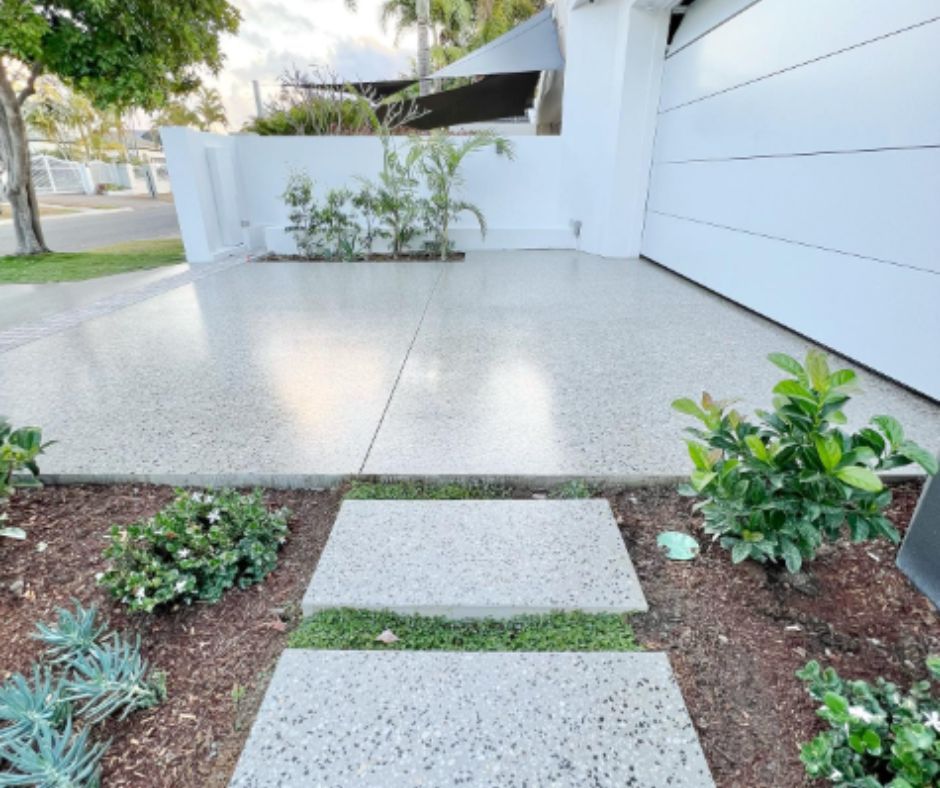

Mechanically polished concrete is typically best for interiors (living areas, kitchens, apartments, showrooms and offices). Outdoors (think driveways, alfresco areas and pool surrounds), a honed and sealed finish with a slip-resistant profile is usually the safer, more compliant choice.

The 8 Factors That Decide If Can Any Concrete Be Polished Safely

If you’re staring at an old slab and wondering, “Can any concrete floor be polished?”, these eight checks are what will give you a clear, honest answer before you commit.

1. Surface Condition & Repairs

Minor hairline cracks, small chips and isolated patches are normal and can usually be repaired before polishing. What raises red flags is widespread delamination, soft or powdery surfaces, or large sections that have been badly patched over time.

2. Age & Existing Coverings

Old slabs are often not a deal-breaker and can actually deliver some of the best polished concrete results once old tiles, vinyl or carpet are removed. After adhesives and grout are taken off and the surface is ground flat, the original concrete is usually a solid candidate for polishing. The only catch is that years of mopping can push dirty water and chemicals into the slab, causing stains that may still show through even after grinding, so the floor can still be polished, but those marks will likely remain part of the final look.

3. Mix, Hardness & Aggregate

Harder, well-cured concrete takes a deeper, longer-lasting polish, while softer mixes can still be polished but usually reach a lower sheen and need more maintenance. How the slab was poured and ground affects the look (from cream to salt-and-pepper to full exposure), and if the mix is patchy, expect more natural variation in the finished floor.

4. Flatness/Level & Edge Access

Polishing machinery works best on slabs that are reasonably flat and accessible. High spots, low spots and tricky edges (around kitchen islands, nib walls or stair nosings) all add time and can limit how even the final gloss appears. On steeply sloped garages or areas with lots of tight corners, a full mechanical polish may not be practical.

5. Moisture/Vapour & Slab Location

On the Gold Coast, humidity, storms and flooding mean ground-level slabs, garages and areas near pools often hold more moisture, which can stop densifiers working properly, make sealers cloudy or peeling, and cause white salts or dark patches. Mechanically polished concrete is best kept indoors where moisture is controlled, while honed concrete or other slip-resistant coatings are usually recommended for outdoor or constantly damp areas.

6. Prior Sealers, Curing Compounds & Contaminants

Old paint, epoxy, thick sealers, curing compounds, oil and grease must be removed before polishing, usually with heavy grinding and sometimes chemical stripping. But some deep stains from oils, adhesives and moisture can leave permanent “shadows” in the concrete, so even after grinding, densifying and polishing, those marks may still show and need to be expected from the start.

7. Usage & Traffic

Floors in busy cafes, garages and retail spaces need tougher finishes, higher exposure levels and sometimes epoxy to handle heavy traffic and chemicals. For typical Gold Coast homes, a well-specified, mechanically polished floor with the right exposure and gloss level will last for years with simple cleaning and occasional rebuffing.

8. Aesthetics & Slip Requirements

Your desired look has to line up with what the slab can actually provide. If you want a high-gloss, mirror-like finish but the concrete is heavily patched and stained, you may be happier with a honed finish or epoxy that hides more of the history.

Around pools, outdoor steps and sloping driveways, slip resistance comes first. Australian standards call for higher slip ratings in wet areas, so we’ll lean towards honed finishes with penetrating sealers or textured systems that keep your family and guests safe without sacrificing style.

When Polishing Isn’t the Best Idea

Polished concrete may not always be the best option and a good contractor will tell you that early. They will usually steer you away from polishing when they see:

- Excessive moisture readings that won’t stabilise

- Major structural cracking, movement or subsidence

- Very soft, crumbly or “dusting” concrete that breaks up under grinding

- Severe oil, chemical or rust contamination that keeps bleeding back

- Extremely uneven surfaces or patchwork repairs that would look messy once exposed

In these cases, forcing a mechanical polish can leave you with a floor that looks worse than when you started.

If Your Slab Fails the Checklist: Best Alternatives That Still Look Premium

If your slab doesn’t tick all the boxes, you still have plenty of good-looking options that suit your Gold Coast homes and businesses.

Grind & Seal

A grind & seal involves grinding the slab to your chosen exposure, then applying a high-quality sealer in matte, satin or gloss.

Honed Concrete

For driveways, paths and pool surrounds, honed concrete is often the smart choice. The surface is prepped and ground to expose the aggregate, then finished with a penetrating or film-forming sealer and a slip-resistant profile.

Epoxy Flooring

Epoxy systems shine in garages, workshops, home gyms and commercial back-of-house areas. If your garage slab is heavily stained or patched, a well-specified epoxy can visually reset the entire area.

The Polishing Process (What to Expect with Coulson’s Concrete Finishes)

When you book a quote with Coulson’s Concrete Finishes, here’s what the typical polishing journey looks like.

Assessment & Testing

We start with a site visit to check the slab condition, flatness and access. Moisture and hardness checks help us understand how the concrete will respond. We’ll also talk through your preferred aggregate exposure and gloss level so expectations are clear before any work starts.

Prep & Repairs

Existing coatings, adhesives, tiles or vinyl are removed as required, then carry out crack and hole repairs. On the Gold Coast, we often encounter tile “grid” marks and old glue, this stage is where we see how deep those issues run and advise you on what will realistically remain visible.

Progressive Grinding & Honing

Using industrial grinders with diamond tooling, we work through multiple passes to flatten and refine the surface. Higher-end finishes and higher gloss levels require more passes, and therefore more time, than a low-sheen or industrial-style finish.

Densify, Polish & Seal

A liquid densifier is applied to harden the surface, helping it hold a better polish and resist wear. We then move through finer grits to bring up the sheen, before finishing with an appropriate penetrating or topical sealer, depending on the system.

Protection & Handover

Once complete, we clean down, apply any final protective measures and walk you through how to look after your new floor. You’ll get clear guidance on cleaning products, maintenance intervals and what to avoid so your finish looks good for years, not just months.

Expert Care & Maintenance Tips for Polished Concrete

Polished and sealed concrete is low-maintenance, but it’s not no-maintenance – especially in sandy, coastal areas. A few simple habits keep it looking its best.

- Dry mop daily with a microfibre dust mop to remove sand and grit that can act like sandpaper.

- Use a pH-neutral cleaner for weekly or fortnightly mopping, harsh chemicals can dull the finish over time.

- Place mats at entries and soft pads under furniture to minimise scratching and wear in high-traffic spots.

- Spot-clean spills immediately, particularly acidic products like wine, soft drinks or citrus.

- Avoid harsh products such as citrus-based degreasers, bleach and abrasive powders.

- Plan periodic maintenance, from a deep clean and reseal (for grind & seal/honed) to an occasional rebuff for mechanically polished floors.

With these basics in place, a well-installed concrete finish will handle Gold Coast humidity, sandy feet and day-to-day family life with ease.

Decision Flow: Can All Concrete Be Polished In Your Space?

Work through these questions and you’ll quickly see whether polishing is realistic or if an alternative makes more sense.

1. Is your slab cured (new) or structurally sound (existing)?

- Yes → Go to Question 2

- No / Not sure → Get a professional assessment; alternatives like epoxy or resurfacing may be safer.

2. Any major moisture issues or significant cracks?

- No, it’s dry and stable → Go to Question 3

- Yes → 2a. Can moisture and cracks be managed with repairs and prep?

- Yes → Once addressed, go to Question 3

- No → Consider honed, grind & seal or epoxy instead of full mechanical polish.

3. Does your desired look match what the slab can reveal? (Think stains from old tiles, oil in garages, patchwork repairs.)

- Yes, I’m happy to see some character and history → Polished concrete is likely viable.

- No, I want a very uniform, “perfect” look → You may be better off with epoxy or another system that hides the slab’s imperfections.

If you’re stuck between answers, that’s where an on-site inspection from a specialist like Coulson’s Concrete Finishes makes the decision much easier.

Conclusion

So, can any concrete floor be polished to a high-end finish? In most Gold Coast homes and businesses, yes, provided the slab is sound, dry and properly prepared. Old slabs under tiles, vinyl or carpet are often ideal candidates once the coverings and glues are removed and the surface is professionally ground.

When moisture, structural issues, soft concrete or severe staining get in the way, there’s no need to force it. Options like honed concrete and epoxy flooring can deliver the look and performance you’re chasing, often faster and with fewer compromises.

If you’d like a straight answer for your specific slab, the best next step is to

schedule a site visit. Coulson’s Concrete Finishes can assess your concrete in person, talk you through what’s realistically achievable and recommend the finish that will still look good years down the track.

Key Takeaways

- Most slabs are polishable with prep, but soft, saturated or badly damaged concrete may be better suited to alternative finishes.

- Older slabs are often fine once coverings, glues and coatings are removed and the surface is ground flat, just be prepared for some character and possible stains that still show through.

- The right finish should match the location (indoor vs outdoor), traffic levels and slip-resistance needs, especially around pools and driveways.

- If conditions aren’t ideal for full mechanical polishing, grind & seal, honed concrete and epoxy can still deliver a premium, low-maintenance result.

Frequently Asked Questions

Can any concrete floor be polished?

In many cases, yes, older slabs polish up beautifully once tiles, vinyl, carpet and adhesives are removed and the surface is ground flat. The key is making sure the concrete underneath is sound, dry and not crumbling. An on-site inspection will reveal whether it’s better suited to a full mechanical polish or a grind & seal style finish.

What’s the difference between polished concrete and grind & seal?

Mechanically polished concrete hardens the slab with densifiers and brings up the shine through multiple stages of grinding and polishing. A grind & seal, on the other hand, relies on a topical sealer to create the final sheen and protection after the slab has been ground. Both can look fantastic, the right choice depends on your slab, budget and maintenance preferences.

Is polished concrete suitable outdoors?

For most outdoor areas, especially around pools, on sloping driveways and exposed patios, we recommend honed or textured finishes rather than high-gloss polished concrete. These systems are designed to achieve better slip resistance in wet conditions while still showcasing the aggregate and giving that resort-style look.

Will cracks show after polishing?

Fine, hairline cracks often remain visible and become part of the character of the floor, especially in older homes. Structural cracks are repaired before polishing, but depending on the exposure level you choose, you may still see subtle lines or infill. If you’d prefer to hide cracks as much as possible, we may recommend a heavier grind, full exposure or an epoxy system.

How long does polished concrete last?

With quality installation and sensible maintenance, a polished concrete floor can last for decades. Indoors, it stands up exceptionally well to family life and commercial traffic. Over time, you may choose to have the surface rebuffed or resealed (for grind & seal/honed systems), but you’re working with the original structural slab rather than a thin surface material that wears out.

Do pets scratch polished concrete?

Polished and honed concrete is very pet-friendly. Dog claws are unlikely to scratch the surface in any noticeable way, especially compared with timber or soft vinyl. The bigger consideration is traction, very high-gloss finishes can feel slippery for older pets, so many owners opt for a matte or satin sheen in living areas.

What finish should I choose, matte or high gloss, and what exposure level?

The decision comes down to how you use the space and the look you love. High gloss with full exposure aggregate can feel like a luxury showroom, but it will highlight dust and marks more. Matte or satin finishes with salt-and-pepper exposure suit busy family homes and coastal lifestyles, hiding day-to-day wear a little better. During your quote, we can show you real examples to help you decide.

How is moisture managed before polishing?

We use moisture meters and visual checks to assess each slab. If readings are high, we may recommend extra drying time, drainage improvements or alternative systems less sensitive to moisture. If the slab won’t dry to a safe level, we won’t push ahead with a full mechanical polish.

What prep is needed before you arrive?

Before we start, we’ll ask you to clear furniture and belongings from the work area and ensure there’s access to power and water. It also helps if you’ve already thought about the kind of look you’re after, gloss level, aggregate exposure and the size of the area to be polished. We’ll fine-tune the details with you on-site.

What if my slab has sealer, paint or old glue on it?

That’s an extremely common scenario, especially in garages and renovated living areas. We can almost always remove old sealers, paint and glues through grinding and, where needed, chemical stripping. However, some deep stains from years of tile cleaning, trapped moisture or stubborn adhesives may leave a permanent stain in the concrete. The floor can still be polished, but those marks may remain as part of the finished result and we’ll always point that out before you commit.